THE CONCEPT

OUTLINE OF CAPABILITIES

Magplanes are high speed vehicles that can be boarded at conveniently located magports which will enable passengers to commute short distances or travel 400 km and more.

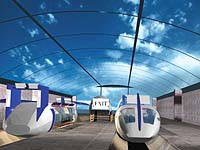

A Magplane System consists of an elevated aluminum guideway (magway) through which independent magnetically levitated vehicles (Magplanes) respond to "Dynamic Scheduling" to and from conveniently located magports. "Dynamic Scheduling" enables Magplanes to be available to passengers using real time analysis of ticket purchases. No passenger will have to wait more than fifteen minutes and yet most trips will be non-stop.

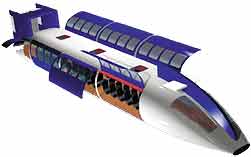

A Magplane resembles a wingless airplane that floats 10 cm above an elevated "magway" trough. A Magplane ride will be smoother and more comfortable than a plane. Magplanes are sized to carry from 80 to 250 passengers and can be designed to carry priority freight. Priority freight traffic is anticipated to greatly increase with the expansion of e-commerce.

Magways are light structures that follow highways and arc gracefully around and over interchanges. Magports can be located at malls, downtown centers, office and industrial parks, airports and vacation sites. In other words, where people live, work, shop and play.

The elevated magway can be built above or adjacent to existing highways and therefore the environmental impact is minimal. Magplanes carry no fuel, emit no fumes or noise, and the individual vehicles need only one tenth the wayside power necessary for the acceleration of conventional high speed electric trains.

A large size intercity Magplane can carry 175 passengers and attains its cruising speed in 1.5 km. At a head way of 60 seconds this permits a capacity of 10,000 passengers per hour each way, and with three coupled vehicles, capacity on high-density routes can be up to three times higher. This can be compared to a light rail system with about 10,000 passengers per hour, and highway lanes of about 3,000 passengers per hour.

A Magplane System can reduce the need for more highways. Personal mobility may no longer be constrained by greater travel demands aggravating gridlocked highways, airports and airways, and adding to air and noise pollution.

ENVIRONMENTAL CONSIDERATIONS

One of the most significant environmental benefits to be gained from the use of the Magplane System will be the reduction in the growth of automobile exhaust emissions. Automobiles are the largest source of air pollution, and a major contributor to the "Greenhouse Effect". Because Magplane vehicles are able to transport large numbers of people and significant amounts of freight, Magplane can reduce the growth of vehicular traffic, air pollution and congestion.

A great advantage of the Magplane System over conventional high speed ground systems is that it is designed to operate at full speed within existing highway rights-of-way. A Magplane is the only high-speed ground system that can bank like a plane and therefore greatly reduce or minimize the need to acquire new and straighter routes. Because of this, cost for land acquisition and the impact on environmentally sensitive lands can be minimized.

Because of the low contact pressure of Magplane vehicles, the supporting guideways and pier foundations will be much smaller than conventional train and roadway bridge construction.

The smaller required footings minimize and localize the potential environmental impact within the construction area. In addition, the elevated magway lends itself to construction techniques which allow for additions from the end of magway spans and above sensitive areas. This construction method virtually eliminates land surface alterations with the exception of pier placement.

Because of the Magplane's ability to climb grades, limited only by passenger comfort, and to utilize existing highway corridors, flood plain management can be only minimally affected. Since the Magplane's guideway is elevated, large areas of cut and fill to achieve operating grade elevations are not necessary. Magplane guideways will also be able to span navigable waterways with sufficient elevation to allow for uninterrupted ship traffic without drawbridges.

The Magplane system can have a significant impact on the future management of greenhouse gas emissions by relieving future growth of road transport. Road transport accounts for 80% of the transportation emissions. To meet the Kyoto Protocol commitments, the transportation sector has to achieve a target emissions reduction of 32% by 2010.

THE NEED FOR A NEW APPROACH TO PUBLIC TRANSPORTATION

Safe, reliable and cost-effective public transportation is one of the world's most pressing needs. Mass transportation by personal vehicles causes a host of problems such as increasing congestion, pollution, environmental degradation, high injury and fatality rates, and excessive reliance upon fossil fuels. In addition, the operational range of highway travel is becoming constrained by a lack of land to site new freeways and by significant environmental concerns, such as global warming.

Air transportation requires large, centralized hubs to operate profitably. North America's newest airports, Dallas-Fort Worth, and Denver International, each use over fifty square kilometers of land to house the requisite infrastructure. The movement of traffic to and from these central hubs also creates congestion problems. Increasingly, under these constraints, air travel has become unsuited for short-distance trips.

Rail transportation, including electric trains, is safe, clean, and inexpensive. However, speed and capacity are limited. Because of physical constraints, convenience to the traveler is relatively low. Building new rail corridors requires long, straight, rights-of-way which are no longer available in medium to densely populated areas. While rail technology can be adapted to permit speeds in excess of 250 km per hour, increased speeds require long, straight and level grades, and more distance between stations and between trains to accommodate acceleration and deceleration. Conventional and newer high speed rail systems cannot serve a decentralized population.

Magplane Technology Inc. has developed a system that has successfully integrated a number of disciplines that collectively result in a newer and better solution to high speed transportation. MTI's proprietary technology and wholly owned patents have enabled it to design a transportation system unlike any other. This system provides an economical and environmentally acceptable alternative to high speed trains, commuter planes, and also, to a large extent, automobiles and intercity buses. Magplane also provides a system so flexible and efficient that it can compete effectively with planes, trains and automobiles at certain distances and have a profound impact on stimulating and managing future growth in an environmentally sustainable manner.

Magplane is not a faster railroad, but a high-capacity means to provide continuous traffic flow along magways, installed either within existing highway right-of-ways, or through and to previously inaccessible locations. It can serve closely spaced magports located off-line at major malls or transportation centers many kilometers apart. It can interface with existing transportation systems or provide an entirely new transportation infrastructure. Magplane offers a realistic alternative to the automobile because it offers similar convenience without the limited range and capacity constraints, and as such is not just an alternative to rail and air travel.

ECONOMIC CONSIDERATIONS

Magplane's flexibility and service to an increased passenger base will result in "induced demand". Trips that heretofore were not considered because of time, distance, and cost can now be feasible. People can live at considerable distance from their jobs and still commute in a reasonable time, for reasonable cost.

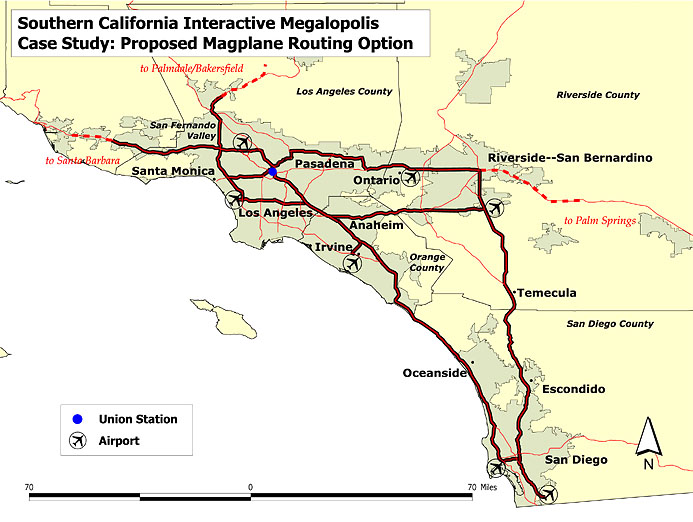

The ability to collapse distances separating the major metropolitan regions of heavily urbanized corridors such as Southern California and the Northeast Corridor in the United States can radically alter travel patterns as more commuters become accustomed to traveling beyond the limited confines of the metropolis.

The capacity limits for the Magplane Commuter Service will resemble the subway systems of North America. With single intercity vehicles, the estimated hourly capacity is 10,000 passengers in one direction, and with three linked vehicles, three times higher. Using linked Intracity vehicles, capacities equal to any of the major world metro systems can be achieved.?

In studies performed for the US Federal Railroad Administration (FRA) (High Speed Ground Transportation for America, 1997), the operating and maintenance cost for an intercity maglev system in California was estimated to be 6.6 cents per revenue passenger mile. Factors such as level of service, traffic volume, route length, passenger-miles per train-mile, load factor, passenger-miles per gross ton-mile, passenger-miles per train-hour, and average trip length influence the operating costs of maglev service. Other corridor operating and maintenance cost estimates in the FRA study hovered between 10 and 13 cents a mile.

Magplane is not a faster railroad, but a high-capacity means to provide continuous traffic flow along magways, installed either within existing highway right-of-ways, or through and to previously inaccessible locations. It can serve closely spaced magports located off-line at major malls or transportation centers many kilometers apart. It can interface with existing transportation systems or provide an entirely new transportation infrastructure. Magplane offers a realistic alternative to the automobile because it offers similar convenience without the limited range and capacity constraints, and as such is not just an alternative to rail and air travel.

These US FRA cost models were predicated on an intercity maglev service that emulated a labor intensive intercity railroad service, complete with reservations systems, baggage handling, catering services and other station facility costs, including on board personnel such as attendants, conductors and engineers. Popular cost effective regional airlines routinely operate in markets where operating costs fall below 10 cents per passenger mile. For example, Southwest Airlines offered a discount fare of $36 one-way between Los Angeles and Oakland in December of 1999, a flight distance of about 350 miles, representing a per passenger mile revenue of about 10 cents.

To eliminate unnecessary costs, the designers of the Magplane Commuter Service for the Interactive Megalopolis will build a cost effective long distance mass transit intracity service without reservations systems and baggage handling and catering services. Automated Magplane vehicles with one attendant per vehicle will reduce labor costs significantly. The Magplane Commuting Service will be designed to achieve a revenue passenger operating and maintenance cost below five cents a mile, permitting a per passenger operating cost of no more than $10 between Boston and New York City, $4 between New York City and Philadelphia, or $6 between Los Angeles and San Diego. The ability to recoup capital costs is facilitated by the high capacity of the Magplane Commuter Service coupled with low operating costs, by distributing the capital payback charge over a greater number of induced passengers.